How Ultrasonic Distance Sensors Work

Ultrasonic distance sensors operate on the principle of echolocation, similar to how bats navigate using sound. The sensor emits a high-frequency sound wave, typically in the ultrasonic range (above 20 kHz), and waits for the echo to return after bouncing off an object. The time taken for the sound wave to travel to the object and back is measured, allowing the sensor to calculate the distance using the formula:

Distance=Speed of Sound×Time2\text{Distance} = \frac{\text{Speed of Sound} \times \text{Time}}{2}

The division by two is necessary because the measured time includes the journey to the object and back. Ultrasonic sensors can provide distance measurements ranging from a few centimeters to several meters, depending on the sensor's specifications.

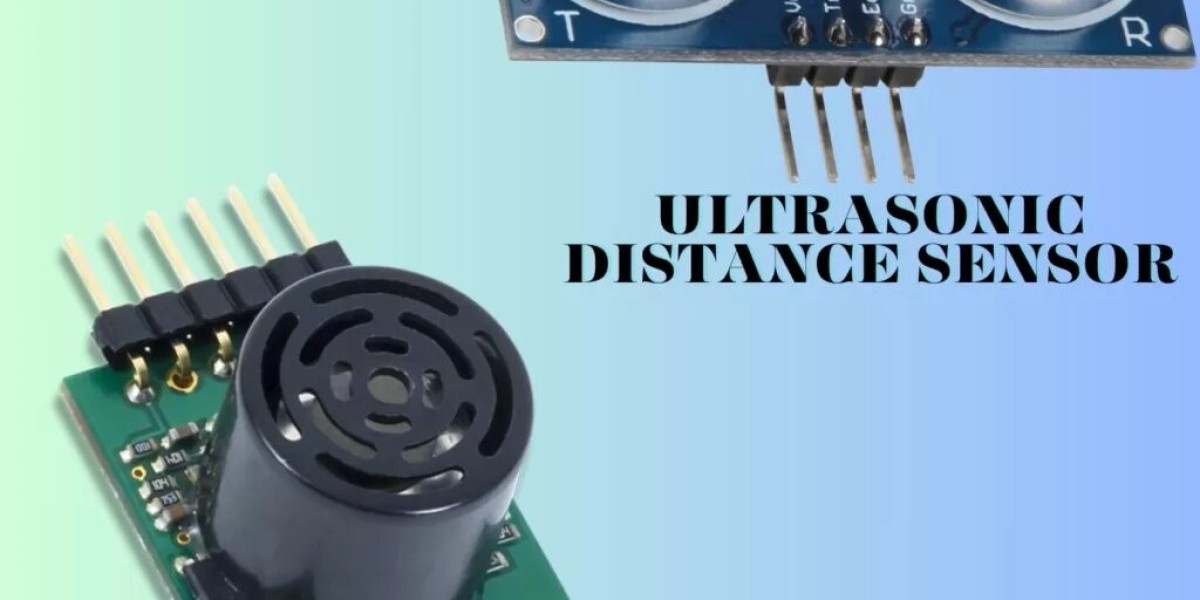

Key Components of Ultrasonic Sensors

- Transmitter: The component responsible for emitting ultrasonic sound waves.

- Receiver: The component that detects the echo of the sound wave after it bounces off an object.

- Control Circuitry: The electronic components that process the signals and calculate the distance based on the time delay.

Applications of Ultrasonic Distance Sensors

Ultrasonic distance sensors have a wide range of applications across various fields:

Robotics: Used in autonomous robots for obstacle detection and avoidance. These sensors help robots navigate their environments by measuring distances to surrounding objects.

Industrial Automation: Employed in manufacturing and warehousing for measuring the fill levels of bins and tanks, monitoring the positioning of materials, and automating assembly lines.

Automotive Industry: Used in parking sensors to detect obstacles when parking, enhancing safety and convenience for drivers.

Smart Home Devices: Incorporated into home automation systems for functions like automatic lighting and security systems that can sense intruders based on proximity.

Agriculture: Utilized in precision farming for monitoring crop heights and managing irrigation systems by measuring water levels.

Advantages of Ultrasonic Distance Sensors

Non-contact Measurement: Ultrasonic sensors can measure distances without physical contact with the object, making them suitable for delicate or moving objects.

High Accuracy: These sensors provide accurate measurements, typically within a few millimeters, making them ideal for applications that require precision.

Versatile: They can operate in various environmental conditions, including dust, humidity, and temperature fluctuations, although extreme conditions may affect performance.

Cost-effective: Ultrasonic distance sensors are relatively inexpensive compared to other distance measurement technologies, such as laser sensors, making them accessible for various applications.

Conclusion

Ultrasonic distance sensors have become indispensable tools in modern technology. Their ability to provide accurate, non-contact distance measurements makes them versatile and widely applicable across various industries. As technology continues to advance, the potential applications of ultrasonic sensors will likely expand, further cementing their role in automation and smart technologies. Understanding how these sensors work and their benefits can help businesses and individuals leverage their capabilities for improved efficiency and safety.

Naijamatta is a social networking site,

download Naijamatta from Google play store or visit www.naijamatta.com to register. You can post, comment, do voice and video call, join and open group, go live etc. Join Naijamatta family, the Green app.

Click To Download