The global cable trays market is expected to grow at a compound annual growth rate (CAGR) of 8% during the forecast period of 2024 to 2032. This growth can be attributed to the increasing demand for safe and efficient cable management systems in various industries, including construction, energy, manufacturing, and telecommunications. With the rapid growth of infrastructure projects, technological advancements in cable systems, and rising investments in industrial automation, cable trays have become indispensable for organizing and protecting electrical wiring in buildings and industrial facilities.

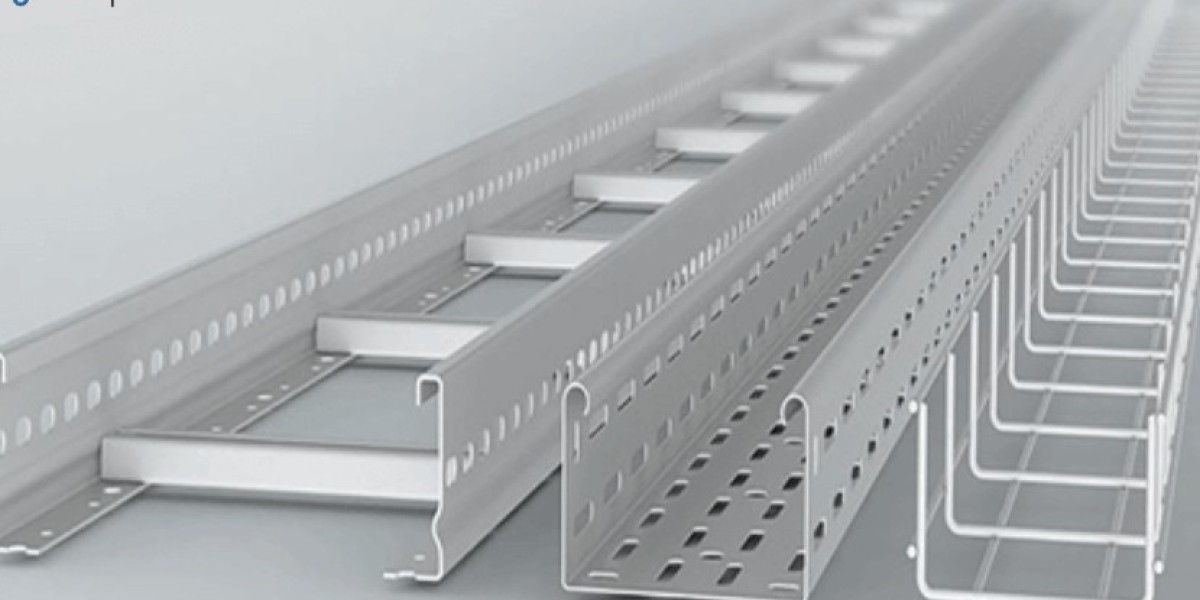

Cable trays provide an ideal solution for managing complex networks of electrical and communication cables, ensuring both safety and operational efficiency. They come in various materials, such as steel, aluminum, and fiberglass, each offering distinct advantages depending on the specific application. The global market for cable trays has seen significant transformation over the years, with developments in design, material, and installation methods, making them a vital part of modern electrical and communication infrastructure.

In this article, we will explore the key trends, drivers, and challenges shaping the cable trays market. We will also delve into market segmentation, regional analysis, competitive landscape, and the outlook for the market from 2024 to 2032.

Market Overview

Cable trays are systems designed to support and organize cables in commercial and industrial installations. These trays provide a safe and effective solution for routing power, data, and communication cables through buildings or plants. Typically installed along walls or ceilings, cable trays help maintain neatness, prevent cable damage, and allow for easy maintenance and upgrades.

The use of cable trays offers several advantages over traditional methods of cable management, such as conduits and ducts. They provide more flexibility, ease of installation, and cost-efficiency, making them suitable for large-scale industrial plants, commercial buildings, and even residential complexes. In addition, cable trays contribute to safety by preventing cables from overheating and reducing fire risks by allowing adequate ventilation.

Key Factors Driving Market Growth

Several factors contribute to the growth of the global cable trays market, including:

- Increased Infrastructure Development: The rapid growth of commercial and residential construction projects across emerging economies has boosted the demand for effective cable management solutions.

- Rise in Industrial Automation: As industries increasingly turn to automation, the demand for sophisticated cable management solutions has grown, with cable trays being a preferred choice for organizing wiring systems in automated environments.

- Technological Advancements: The development of new materials, such as corrosion-resistant alloys and fire-resistant fiberglass, has enhanced the functionality of cable trays in harsh environments.

- Focus on Safety: With rising awareness about electrical safety, the need for proper cable management to prevent accidents, such as electrical fires and short circuits, is driving the demand for cable trays.

- Environmental Considerations: Cable trays are increasingly seen as more eco-friendly alternatives to other cable management systems, given their ability to promote efficient cable organization and reduce the need for extensive materials.

Get a Free Sample Report with Table of Contents

Market Segmentation

The global cable trays market can be segmented based on material type, installation type, end-user industry, and geography. Each segment offers unique insights into the market dynamics and trends.

Material Type

Cable trays are made from a range of materials, each suited to specific environments and applications. The major materials used in cable tray construction are:

- Steel Cable Trays: Steel is the most commonly used material due to its strength, durability, and cost-effectiveness. Steel trays are widely used in industrial and commercial applications, especially where high load-bearing capacity is needed.

- Aluminum Cable Trays: Aluminum is a lighter and corrosion-resistant alternative to steel. Aluminum trays are ideal for installations in industries where weight reduction and resistance to environmental factors such as humidity or chemicals are critical. They are also highly preferred for outdoor applications.

- Fiberglass Cable Trays: Fiberglass trays are gaining popularity due to their resistance to corrosion and fire. These trays are commonly used in industries like petrochemicals, pharmaceuticals, and mining, where harsh environments prevail.

- Others (PVC, Stainless Steel): Other materials, such as PVC and stainless steel, are also used for cable trays in specialized applications, particularly in low-risk environments or for specific aesthetic purposes.

Installation Type

Cable trays are installed using different types of setups depending on the location and function:

- Wall-mounted Cable Trays: These are attached directly to walls and are ideal for installations where floor space is limited.

- Ceiling-mounted Cable Trays: These trays are hung from ceilings, commonly used in large industrial facilities, warehouses, and commercial buildings where cables need to be routed across long distances.

- Floor-mounted Cable Trays: Typically used in larger industrial setups, these trays are installed directly on the ground and are often used for heavy-duty installations.

End-user Industry

The demand for cable trays spans various industries, each with unique requirements:

- Construction: The construction industry is one of the largest end-users of cable trays, particularly for the installation of electrical and communication systems in residential, commercial, and industrial buildings.

- Energy & Power: The energy sector uses cable trays extensively for power generation plants, transmission stations, and renewable energy installations.

- Telecommunications: As telecommunications networks expand globally, there is a rising need for efficient cable management in data centres, communication hubs, and telecommunication towers.

- Manufacturing: The manufacturing sector, particularly industries such as automotive and pharmaceuticals, requires robust cable management solutions to handle the complex systems of wiring in automated and production environments.

- Others: Other end-user industries, such as transportation (airports, railway stations), IT/data centres, and healthcare facilities, also contribute to the demand for cable trays.

Geography

Geographically, the global cable trays market is divided into North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa.

- North America: This region leads the market due to the presence of large-scale infrastructure projects, industrial plants, and technological advancements in cable management systems.

- Europe: Europe is another significant market for cable trays, with growth driven by the ongoing development in smart cities, industrial automation, and stringent safety regulations.

- Asia Pacific: The Asia Pacific region is expected to experience the fastest growth during the forecast period, driven by rapid urbanization, industrialization, and rising demand for infrastructure in countries like China and India.

- Latin America and MEA: While the demand for cable trays in these regions is comparatively smaller, growth is anticipated due to infrastructure development projects, particularly in Brazil, the UAE, and Saudi Arabia.

Market Trends

The cable trays market is undergoing significant changes driven by technological advancements, environmental regulations, and evolving industry needs. Some key trends shaping the market include:

Smart Cable Trays

With the growing emphasis on automation and digitalization, manufacturers are integrating smart features into cable trays. These smart cable trays are equipped with sensors that monitor cable health, detect potential hazards such as overheating or damage, and provide real-time data for predictive maintenance.

Sustainable and Eco-friendly Materials

There is an increasing focus on using sustainable and environmentally friendly materials in the production of cable trays. Fiberglass and aluminum are gaining popularity due to their recyclability, while manufacturers are also exploring biodegradable materials for use in non-industrial settings.

Customization and Modularity

As the demand for flexible and scalable cable management systems increases, manufacturers are offering customizable and modular cable tray solutions. These systems can be adapted to specific project requirements, making them highly versatile for both large and small-scale applications.

Prefabrication and Pre-assembly

To reduce installation times and increase efficiency, more companies are opting for prefabricated and pre-assembled cable trays. These solutions allow for quicker deployment, minimising on-site construction work, and improving safety.

Challenges in the Cable Trays Market

Despite the strong growth prospects, the cable trays market faces several challenges that may affect its trajectory:

- High Initial Investment: While cable trays are cost-effective in the long run, the upfront investment can be high, particularly when installing complex systems in large industrial setups.

- Competition from Alternative Solutions: Other cable management systems, such as conduits and ducts, may offer advantages in certain applications, particularly in environments that require higher levels of protection or where space is limited.

- Installation Complexity: In some cases, the installation of cable trays can be challenging, especially in environments with limited access or in retrofit applications.

Competitive Landscape

The cable trays market is highly competitive, with several key players dominating the industry. These companies are focusing on product innovation, strategic partnerships, and mergers and acquisitions to maintain their market positions. Major companies in the market include:

- Legrand: Known for providing high-quality electrical solutions, Legrand has a strong portfolio of cable trays and management systems.

- Schneider Electric: A global leader in energy management and automation, Schneider Electric offers a wide range of cable tray solutions suitable for various industries.

- Atkore International: Specializes in steel and aluminum cable trays, providing solutions for power and telecommunications sectors.

- Panduit: A key player in the cable management industry, Panduit offers modular and custom cable trays designed for high-performance applications.

Explore More Reports:

methacrylic acid Market: https://www.expertmarketresearch.com/reports/methacrylic-acid-market

PDMS Market: https://www.expertmarketresearch.com/reports/pdms-market

Smart Stadium Market: https://www.expertmarketresearch.com/reports/smart-stadium-market

Market Outlook

The global cable trays market is expected to grow at a CAGR of 8% from 2024 to 2032. The increasing demand for organized and safe cable management solutions in industries such as construction, energy, and telecommunications will continue to drive the market's expansion. Additionally, innovations in materials, smart features, and sustainability practices will create new opportunities for growth.

Naijamatta is a social networking site,

download Naijamatta from Google play store or visit www.naijamatta.com to register. You can post, comment, do voice and video call, join and open group, go live etc. Join Naijamatta family, the Green app.

Click To Download