Introduction to PP Corrugated Sheets

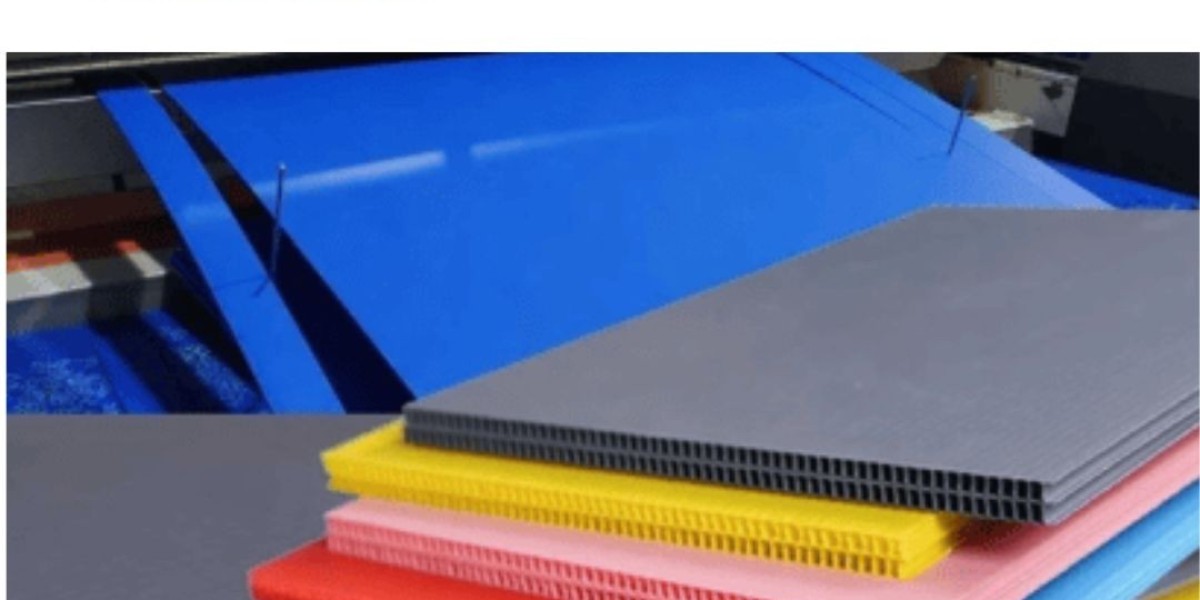

PP corrugated sheets, crafted from high-quality polypropylene, have emerged as a game-changer in various sectors due to their exceptional durability, lightweight characteristics, and versatility. These plastic corrugated sheets consist of two outer layers with a fluted inner structure, providing strength without adding unnecessary weight. Defined by their innovative design, Pulkit Plastic Products stand out for their ability to withstand harsh environmental conditions while maintaining stability. In recent years, these sheets have been adopted across industries such as construction, agriculture, packaging, and signage, showcasing their multifaceted nature and wide-ranging applications.

Structural Properties and Advantages

The structure of a PP corrugated sheet consists of a series of parallel flutes interspersed between two flat sheets of polypropylene. This distinct structure allows the sheets to exhibit impressive strength and rigidity, making them suitable for various applications. The lightweight nature of plastic corrugated sheets means they are easy to transport and handle, significantly reducing shipping costs and labor involved in installation and transportation. Moreover, these sheets are inherently resistant to moisture, chemicals, and UV rays, which allows them to excel in outdoor environments and demanding applications.

Another significant benefit of PP corrugated sheets is their recyclability. As an environmentally friendly option, they can be repurposed or recycled at the end of their lifecycle, thus reducing waste and promoting sustainable practices. Additionally, their affordability compared to other materials like wood or metal positions them favorably in the market, especially for businesses seeking cost-effective solutions without compromising quality.

Applications of PP Corrugated Sheets

The versatility of Plastic corrugated sheets is demonstrated through their wide applications across several sectors. In the construction industry, these sheets are commonly used as temporary barriers during construction projects, as they provide excellent protection against debris and high winds. Their lightweight nature allows for quick installation, enabling contractors to enhance safety on-site without spending excessive time or resources.

In agriculture, PP corrugated sheets serve essential functions such as greenhouse cladding and shade structures. Their ability to deflect UV rays while permitting sunlight to filter through makes them ideal for protecting crops. Additionally, the sheets act as reliable windbreaks and rain shields, creating more favorable growing environments.

Packaging is yet another area where plastic corrugated sheets shine. These sheets are increasingly replacing traditional materials like cardboard and wood due to their durability and moisture resistance. They can be fabricated into various forms, including boxes, containers, and protective wrapping materials, providing superior protection for products during transportation and storage.

Sustainability and Environmental Impact

As environmental concerns escalate globally, the market is increasingly leaning towards sustainable solutions. PP corrugated sheets align well with this trend due to their recyclability and low carbon footprint. The production of polypropylene requires less energy compared to materials like metal and glass, rendering it a more sustainable option in terms of resource use.

Furthermore, businesses are becoming more conscious of the environmental impact of their packaging choices. By shifting to plastic corrugated sheets, organizations can demonstrate their commitment to eco-friendly practices. Many manufacturers today offer closed-loop recycling programs for their products, enabling customers to return used sheets for reprocessing, thus minimizing landfill contributions. This growing trend not only supports sustainable practices but also resonates positively with environmentally aware consumers.

Enhancing Safety and Durability

One of the standout features of PP corrugated sheets is their robust durability. These sheets exhibit superior resistance to impacts, rendering them suitable for demanding applications in various settings. In industries where strength and reliability are paramount, the use of plastic corrugated sheets can minimize the risk of damage to both products and the environment.

Their resistance to moisture fosters an environment where mold and mildew have difficulty proliferating. This characteristic is particularly advantageous in settings like storage and transportation, where goods are prone to damage from humidity. Moreover, the UV resistance of these sheets maintains their structural integrity when exposed to sunlight, elongating their service life in outdoor applications.

In contexts where safety is a concern, such as construction sites or outdoor events, PP corrugated sheets can be employed as protective barriers to delineate work areas or provide shielding against hazards. Their ability to be dyed in various colors further enhances safety by clearly marking boundaries and ensuring visibility for workers and pedestrians.

Customization and Manufacturing Process

Producing plastic corrugated sheets involves a highly sophisticated manufacturing process that ensures quality and customization. The process begins with the extrusion of polypropylene resin into continuous sheets. The extrusion equipment is designed to form the characteristic fluted structure while providing the desired thickness and density, which can be tailored to meet specific customer requirements.

Customization is a hallmark of PP corrugated sheets, allowing manufacturers to produce sheets in various sizes, thicknesses, and colors. Businesses can request properties that align with their unique needs, such as specific weight capacities or additional features like anti-static finishes. This flexibility ensures that industries have access to the correct specifications required for their applications, enhancing operational efficiency.

The potential for digital printing on PP corrugated sheets further increases their appeal. Custom graphics, logos, and designs can be printed directly onto the sheets, empowering businesses to create visually appealing displays or packaging solutions that effectively communicate their brand identity.

Market Trends and Future Outlook

As industries continue to evolve, the market for PP corrugated sheets is poised for significant growth. Increased demand for sustainable packaging solutions and protective materials will drive the expansion of this sector. With manufacturers focusing on innovation, the development of enhanced properties and functionalities will likely take center stage.

Several market reports indicate a growing inclination toward eco-friendly alternatives, indicating a need for businesses to adapt and adopt sustainable materials. Polypropylene recycling technologies will improve, making it easier for businesses to implement circular economy practices in their operations. Additionally, with the advancing techniques in manufacturing, the quality and performance of PP corrugated sheets will continue to rise, further solidifying their place in the market.

Conclusion

The Plastic corrugated sheet are a testament to the advancements in material science and sustainable practices within various industries. Their exceptional durability, lightweight characteristics, and versatility have established them as valuable components in construction, agriculture, packaging, and more. As sustainability takes center stage in global markets, these sheets stand out as an eco-friendly alternative that promotes responsible practices while ensuring quality and performance. With a promising future on the horizon, businesses that invest in PP corrugated sheets are aligned with an innovative approach to material use—one that prioritizes functionality alongside environmental considerations.

Frequently Asked Questions

1. What are the key differences between PP corrugated sheets and traditional cardboard?

PP corrugated sheets are more durable and moisture-resistant than cardboard, making them suitable for outdoor applications. Unlike cardboard, which can weaken and degrade when exposed to water, plastic corrugated sheets maintain their structural integrity in humid conditions. Additionally, PP sheets are reusable, recyclable, and can provide greater protection for products during shipping.

2. Can PP corrugated sheets be printed on for branding purposes?

Yes, PP corrugated sheets can be printed on using various methods, including digital printing. This feature allows businesses to customize sheets with logos, product information, and other branding elements, transforming them into eye-catching displays or packaging solutions.

3. How do I maintain and clean PP corrugated sheets?

Maintaining PP corrugated sheets is straightforward; they can be wiped clean with a damp cloth and mild detergent if necessary. Avoid using harsh chemicals, as they may damage the sheets. For outdoor applications, periodic inspections and cleaning will help prolong the life of the sheets.

4. Are there specific weight limits associated with PP corrugated sheets?

Yes, the weight limit for PP corrugated sheets varies depending on factors such as thickness, sheet size, and the specific manufacturing process. Most manufacturers provide specifications and guidelines regarding load-bearing capacities, and it’s important to consult this information to ensure safe usage in your applications.

Naijamatta is a social networking site,

download Naijamatta from Google play store or visit www.naijamatta.com to register. You can post, comment, do voice and video call, join and open group, go live etc. Join Naijamatta family, the Green app.

Click To Download